Every missed first-time fix sets off a chain reaction: a wasted technician visit, frustrated customers, missed SLAs, and higher costs. For coffee and vending operators, where service quality is just as important as product quality, first-time fix rate (FTFR) is a direct measure of efficiency, profitability, and reputation.

Yet, many operators struggle to improve this key metric.

In this blog, we’ll unpack what FTFR is, why it matters, and the top five ways you can improve it. We’ll also explore how leading operators are using better planning, smarter tools, and connected workflows to consistently improve FTFR and increase their profits.

What is first-time fix rate and how to calculate it?

A first time fix rate (FTFR) is a key performance indicator (KPI) that measures the percentage of service tasks a technician resolves on their first visit, without needing to return with additional parts, information, or assistance. A higher FTFR leads to improved customer satisfaction, increased efficiency, reduced operational costs, and higher technician productivity.

To calculate your first-time fix rate and get an accurate picture of how your field staff are performing, simply divide the total number of jobs fixed on the first visit by the total number of jobs performed.

Formula: (Jobs fixed on first visit ÷ Total jobs) x 100.

For example, if your team handled 500 service calls in a month and fixed 350 on the first visit, your FTFR would be 70%.

Across industries, FTFR benchmarks usually fall between 60–80%. For coffee and vending operators, anything below that creates major inefficiencies. Low FTFR means more truck rolls, higher fuel and labor costs, and unhappy customers who lose trust in your reliability.

The hidden costs of low FTFR go beyond this.

Each repeat visit takes up a new slot on your calendar, eats into profit margins, and puts SLAs at risk. Over time, this can lead to churn and in a competitive market, lost clients are hard to win back.

With the stakes this high, let’s explore 5 ways you can start improving FTFR.

5 ways to improve first-time fix rates

01

Give technicians full job context before arrival

03

Make sure the right part is always in the van

02

Use automated route planning

04

Enable real-time communication

05

Track and improve with the right KPIs

Tip 1: Give technicians full job context before arrival

Too often, technicians arrive on-site without knowing the machine’s service history, recurring issues, or even the model they’re about to work on.

Imagine a vending machine with recurring sensor failures. Without access to history, the technician may only patch the immediate issue. But with visibility into past service notes, they’d spot the pattern and fix the root cause.

The key is making job history, customer notes, and machine details available on mobile devices before a technician ever leaves the depot. With full context, they can walk in prepared, confident, and equipped to deliver a first-time fix.

Now you can do this by maintaining several spreadsheets for different jobs, or you can invest in a CRM that centralizes service tickets and machine history in one view.

Dobby, an all-in-one platform for coffee and vending operators, helps technicians get a full job context on their mobile app, ensuring they know exactly what they’re walking into.

When technicians are prepared, the likelihood of repeat visits drops dramatically. That brings us to the next driver of FTFR: parts availability.

Tip 2: Make sure the right part is always in the van

Which parts are being used most often

What’s running low and needs replenishment

Whether vans are carrying the right critical items

Again, spreadsheets work fine when you only have a few vans and parts to track. But as your business grows, you need to connect parts usage to service tickets, automate replenishment workflows and track van stock in real-time.

This ensures technicians always have the right consumables and spare parts when they arrive.

How Dobby helps:

Dobby integrates inventory management with service tickets. Technicians log part usage on-site, and the system automatically updates stock levels and replenishment needs, removing the guesswork from van stocking.

With the right part in the van, the chances of a first-time fix improve significantly. But even when you’re stocked and ready, poor planning can undermine your team’s productivity. That’s where route optimization comes in.

Tip 3: Use automated route planning

Manual route planning often leads to inefficiency. Technicians crisscross cities, spend hours stuck in traffic, or cover two distant regions in one day, all of which wastes time and reduces capacity.

Evry extra mile is money lost, and every delay means fewer jobs completed. Worse, rushed technicians are more likely to make mistakes or deliver incomplete fixes.

Automated field service route planning solves this by factoring in geography, traffic conditions, technician skill sets, and customer priorities. This ensures the right technician gets to the right job, at the right time.

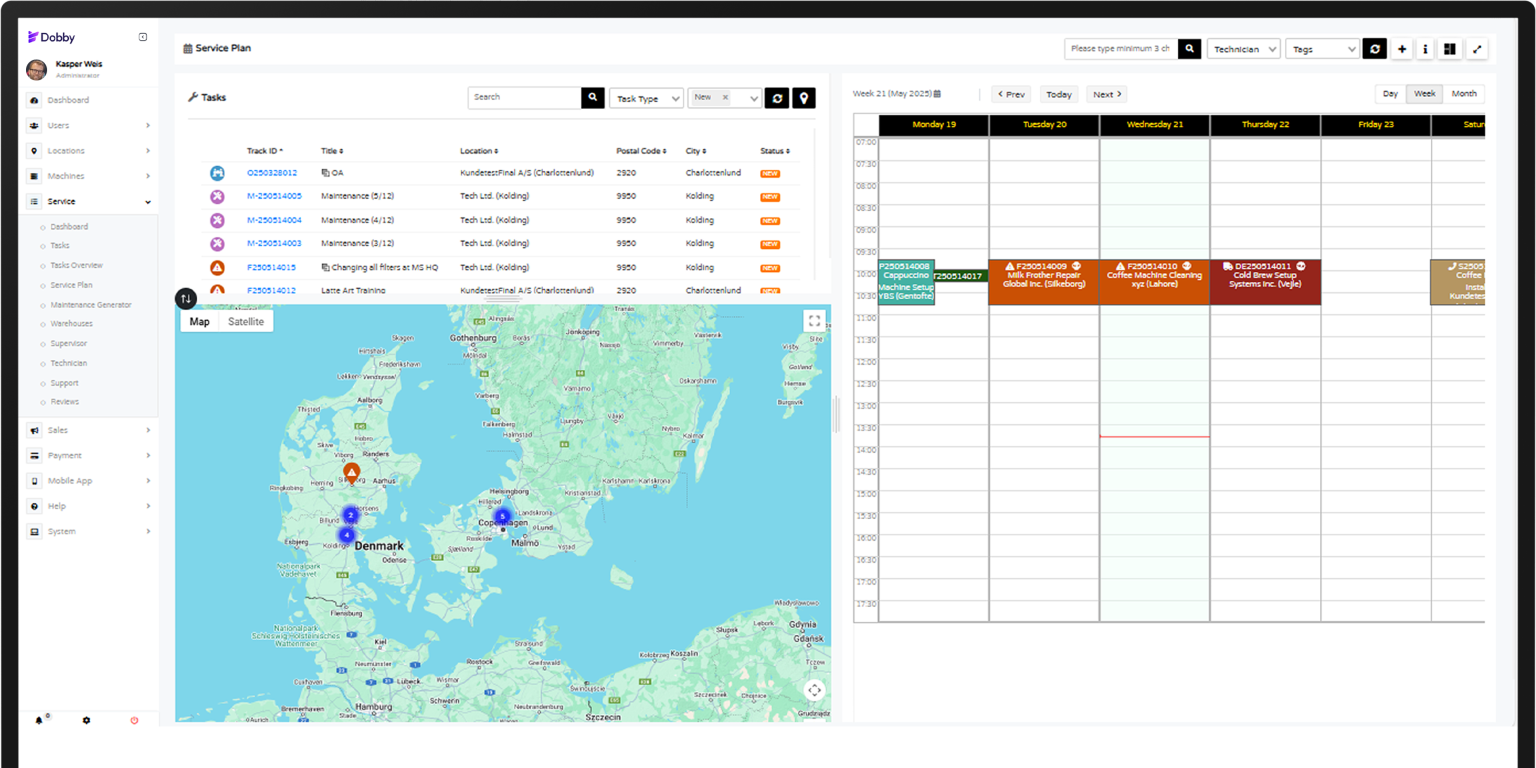

Dobby’s dynamic routing feature matches technicians to jobs based on skills, location, and availability. As a result, more jobs are completed per day, drivers waste less time, and you get a higher FTFR.

And once technicians are en route, real-time communication becomes the next critical piece.

Tip 4: Enable real-time communication & updates

Few things frustrate customers more than waiting half a day for a technician without knowing when they’ll arrive. Lack of updates leads to no-shows, cancellations, and lost trust.

Real-time communication is now an expectation.

Customers want to know when a technician is on the way, if there are delays, and when the job is complete. Without this visibility, service feels unreliable, even if the issue eventually gets fixed.

One way to do this is to constantly ping your customers about your whereabouts. But this might irritate them more and waste your technician’s time.

A better option is using Dobby to equip your team with mobile apps for live updates, automated notifications, and two-way communication, ensuring customers always feel informed and valued.

When communication is clear, customers are more forgiving of delays and more loyal over time. But to make sustainable improvements, you also need to track performance.

Tip 5: Track and improve with the right KPIs

You can’t improve what you can’t measure. While most operators track FTFR, it’s only one piece of the puzzle. To understand the full picture, you also need to monitor SLA adherence, technician field service optimization, and cost per ticket.

For example, a service manager may notice that one technician consistently has lower FTFR. With the right data, they can identify whether it’s a training issue, an inventory tracking issue, or a planning issue and fix it.

Dashboards that bring all these KPIs into one view are critical. They turn numbers into insights, making it easier to identify trends, bottlenecks, and opportunities.

Most operators think it’s the service managers’ job to have a view of these metrics. But if they are spending 20+ hours a week just to identify the root cause of a problem, when would they train technicians?

What helps is having a CRM like Dobby that offers customizable dashboards to track FTFR, SLA compliance, technician utilization, and profitability. This helps service managers gain visibility to make informed decisions that directly improve first-time fix rates.

By consistently measuring and acting on these KPIs, you create a culture of continuous improvement, one where FTFR becomes a strength for your team!

Read on to know more about how Dobby helps with this.

How Dobby can help you improve FTFR

Improving FTFR isn’t about asking technicians to work harder; it’s about giving them the tools, visibility, and structure to succeed. Dobby helps operators achieve this by:

Centralizing service ticket management for full visibility.

Automating technician routing to save time and reduce missed fixes.

Connecting real-time inventory with van stock to ensure the right part is always available.

Equipping technicians with mobile apps for context and communication.

Providing dashboards that track FTFR and other KPIs.

Explore more insights and guides from our experts

1. Choosing field service management software for your coffee service business? Ask these 5 questions first

2. How vending machine management software fixes your data chaos

3. How to grow your coffee service business? 4 steps you can take today