Coffee and vending service operators rely on technicians to keep machines running reliably and clients happy. But behind the scenes, many teams still map out daily routes by hand: juggling spreadsheets, phone calls, and guesswork.

What seems manageable on the surface can quietly drain profits and damage your reputation.

In this post, we’ll uncover 5 hidden costs of manual route planning that could be holding your business back and explore what you can do to fix them. Let’s start with the most common hidden cost, wasted technician time.

01

Wasted technician hours and overlapping routes

02

Rising fuel and vehicle costs

03

Missed SLAs and customer complaints

04

Burnout and turnover in your service team

05

No real-time visibility or data for improvement

Cost 1: Wasted technician hours and overlapping routes

On any given day, your technicians spend countless hours behind the wheel. But not all drive time is productive.

When routes are planned manually, technicians often zigzag across territories, doubling back to the same neighbourhoods or sitting idle in traffic. This results in less time servicing machines, more time burning fuel and patience.

In fact, we found that inefficient routing can increase service call times by 51%.

Plus, overlapping routes don’t just slow your team down. They create unpredictable schedules that frustrate technicians and leave customers waiting.

As you can imagine, this inefficiency has a domino effect. Let’s look at how those extra miles impact your costs.

Cost 2: Rising fuel and vehicle costs

Every unnecessary mile driven chips away at your bottom line. When technicians travel further than needed, you pay twice: once in fuel costs and again in accelerated wear and tear.

These hidden costs can be significant over a year.

Imagine a team of ten technicians each driving just 15 extra miles a day. That’s more than 37,000 wasted miles annually, and thousands in avoidable expenses.

Beyond the financial impact, there’s a reputational cost. More miles mean higher CO2 emissions, which can undermine your sustainability commitments and turn off environmentally conscious clients.

And it doesn’t stop there. Here’s how all this unpredictability affects your customers.

Cost 3: Missed SLAs and customer complaints

Clients depend on timely service to keep their machines stocked and running smoothly. But when technicians are behind schedule, SLAs slip.

Manual planning makes it difficult to predict arrival times or adjust routes on the fly. Even a single delay in the morning can cascade into a day of missed appointments and frustrated clients.

Late or missed service calls damage trust and lead to more complaints, negative reviews, and, eventually, churn. For operators relying on long-term contracts, this can quietly erode revenue without obvious warning signs.

But unhappy customers are only part of the picture. Missed SLAs also take a toll on your technicians.

Cost 4: Burnout and turnover in your service team

A poorly planned day doesn’t just create inefficiencies, it creates stress. When technicians start late or get stuck in avoidable traffic, their shifts often run long. Over time, these extended days lead to burnout, dissatisfaction, and higher turnover.

High churn comes with hidden costs of its own: recruitment, onboarding, and training expenses, not to mention the lost knowledge when experienced team members walk out the door. Burnout affects your culture, too. A team stretched thin is more likely to make mistakes or deliver subpar service.

Cost 5: No real-time visibility or data for improvement

Finally, the last hidden cost of manual planning is a lack of visibility.

When you plan routes in spreadsheets, you’re effectively flying blind. There are no updates when traffic snarls appear or a technician finishes early. You can’t easily see which clients drain resources or which regions are under-serviced. And you don’t get the data you need to identify patterns or improve processes.

Without this visibility, you lose the ability to spot inefficiencies, optimise schedules, and make informed decisions.

To avoid these hidden costs, many businesses in the coffee and vending machine service industry are already using automation to gain an edge. Which means sticking to manual processes leaves you at a clear disadvantage that will only widen over time.

Fortunately, there’s a better way forward.

How Dobby eliminates these hidden costs

If any of these hidden costs we discussed above feel familiar, you’re not alone. Manual route planning holds back even the most dedicated teams.

That’s why Dobby’s intelligent route planning platform was built. To help coffee and vending operators move past the chaos of manual scheduling.

With Dobby, you can:

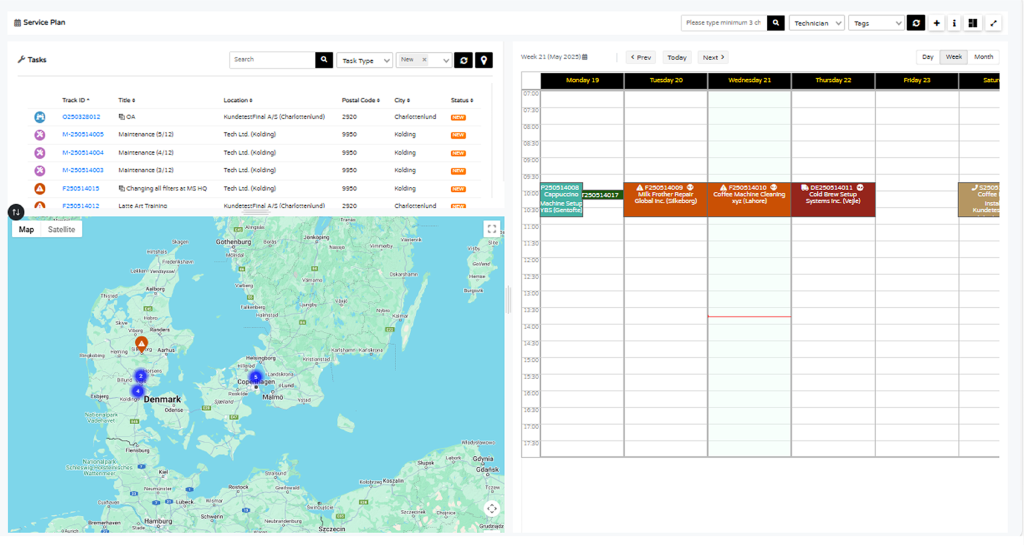

Automate scheduling:

No more spreadsheets or guesswork. Create optimised plans in minutes.

Optimise routes:

Technicians visit more clients in less time, reducing fuel and overtime.

Get real-time updates:

Dispatch teams can adjust routes on the fly when priorities chang

Track technicians live:

Know where your team is and when they’ll arrive.

Unlock data-driven insights:

Understand which routes, clients, and regions are most profitable.

Dobby helps you deliver exceptional service, protect your margins, and build a business that runs as smoothly as your best machines. Companies using Dobby have reported a 51% increase in service efficiency and up to 11% reduction in customer churn.

This isn’t just software, it’s the foundation to scale your operations without scaling the chaos.

Talk to our experts to see how much you could be saving and learn how to cut these hidden costs for good.