Warehouse Management

Built for

growing operations

Manage inventory across warehouses, vehicles, and regions from one system. Scale confidently without losing visibility or control.

Teams improve retention rates by up to 40%

with live customer feedback.

Overview

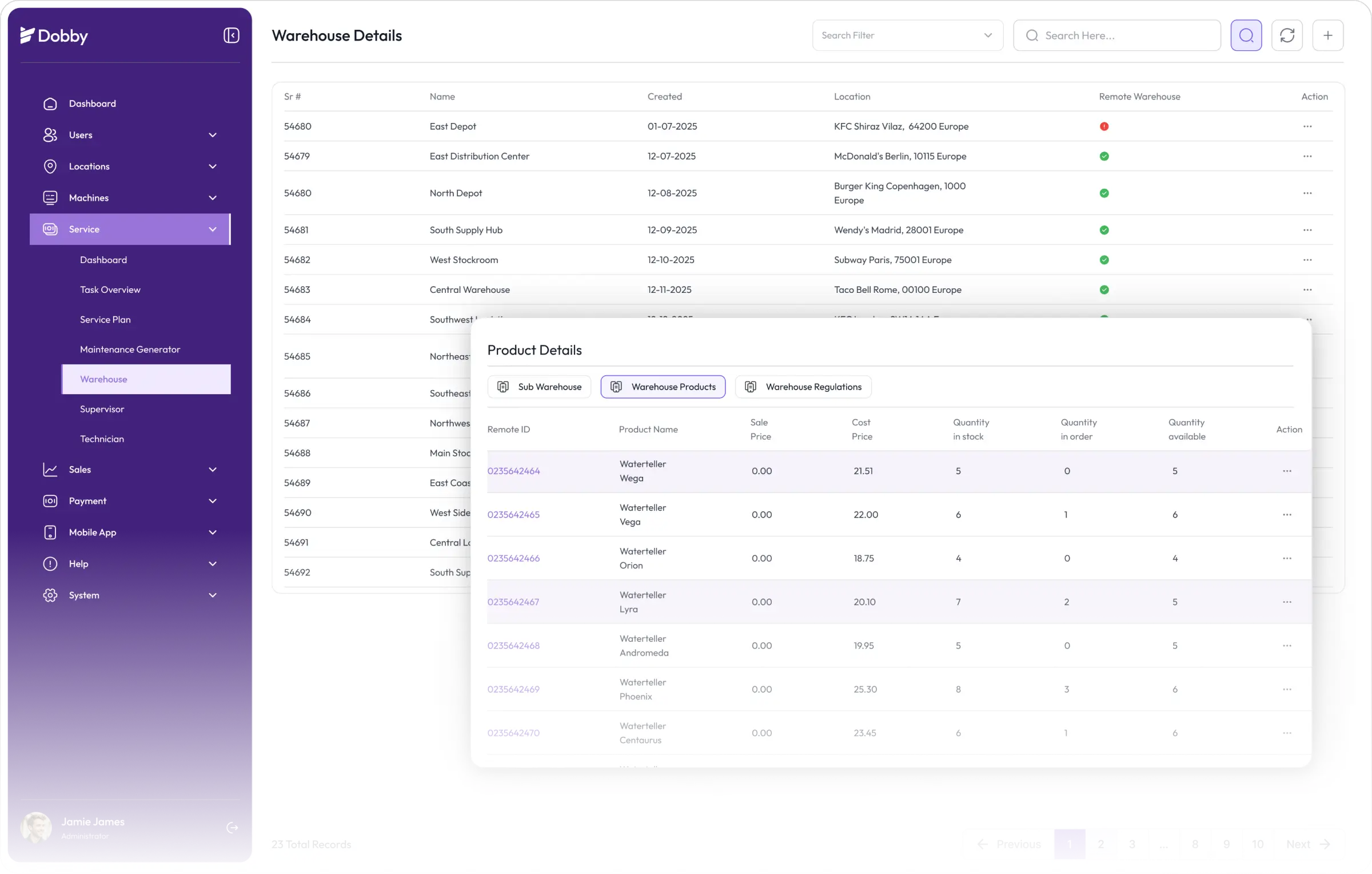

Inventory, fully controlled

Manage stock across warehouses and vehicles in real time. Prevent shortages, reduce excess inventory, and keep technicians prepared.

Live Inventory

Track stock across warehouses and technician vehicles in real time. Always know what’s available, needed, and where it is.

Balanced Stock

Avoid shortages and excess inventory. Automated reorder levels keep stock optimized without manual tracking or last-minute surprises.

ERP Connected

Sync inventory directly with your ERP. Keep stock levels accurate, reduce manual work, and improve forecasting automatically.

Vehicle Stock

Manage parts in technician vehicles. Equip teams correctly, reduce repeat visits, and improve first-time fix rates.

Multi-Location Ready

Control inventory across multiple warehouses and regions. Centralize stock management and scale operations without added complexity.

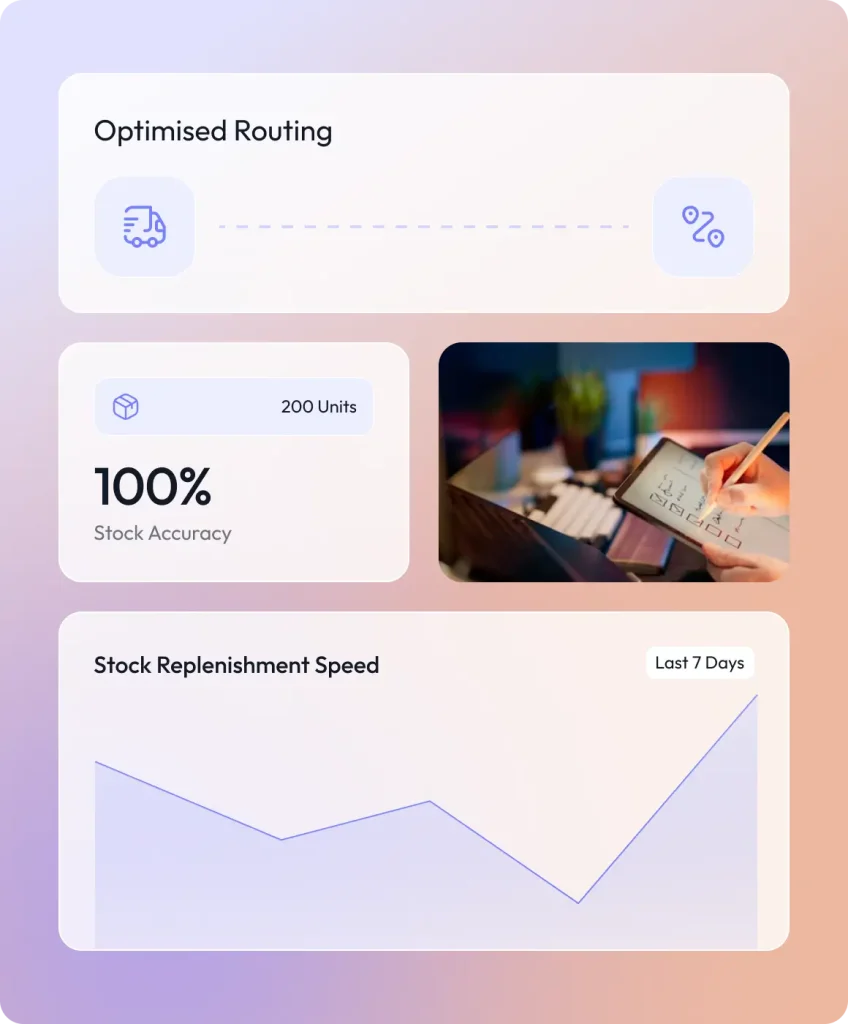

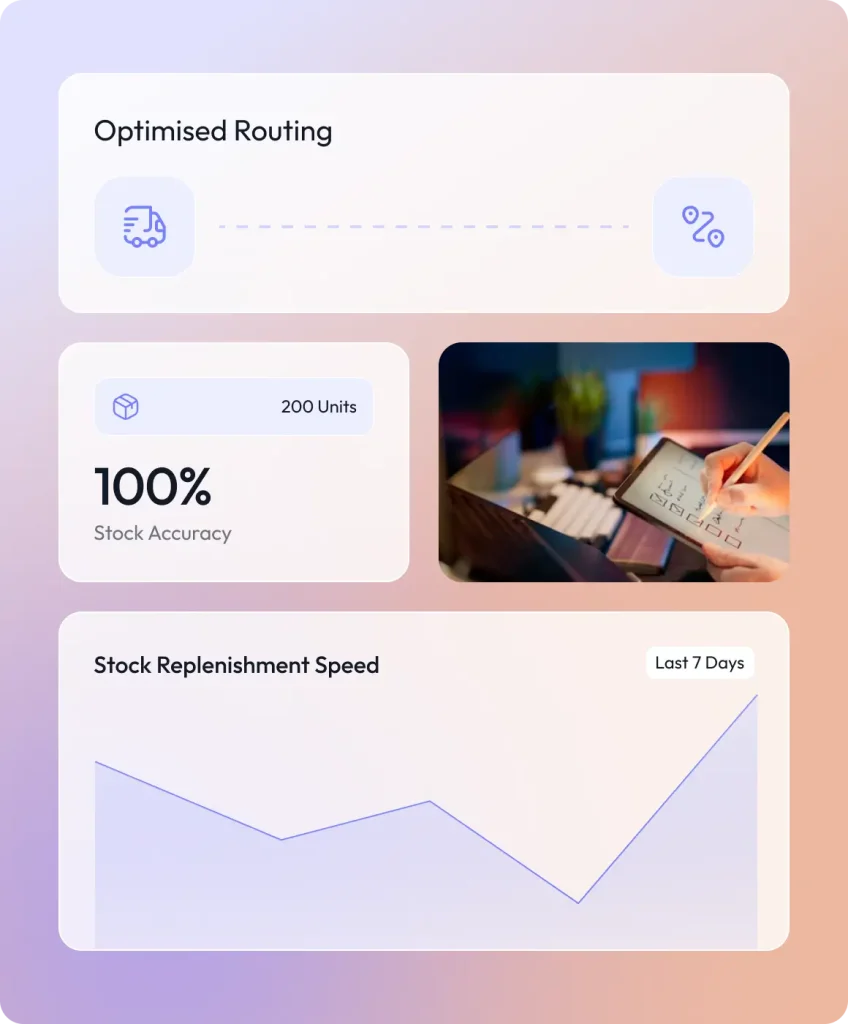

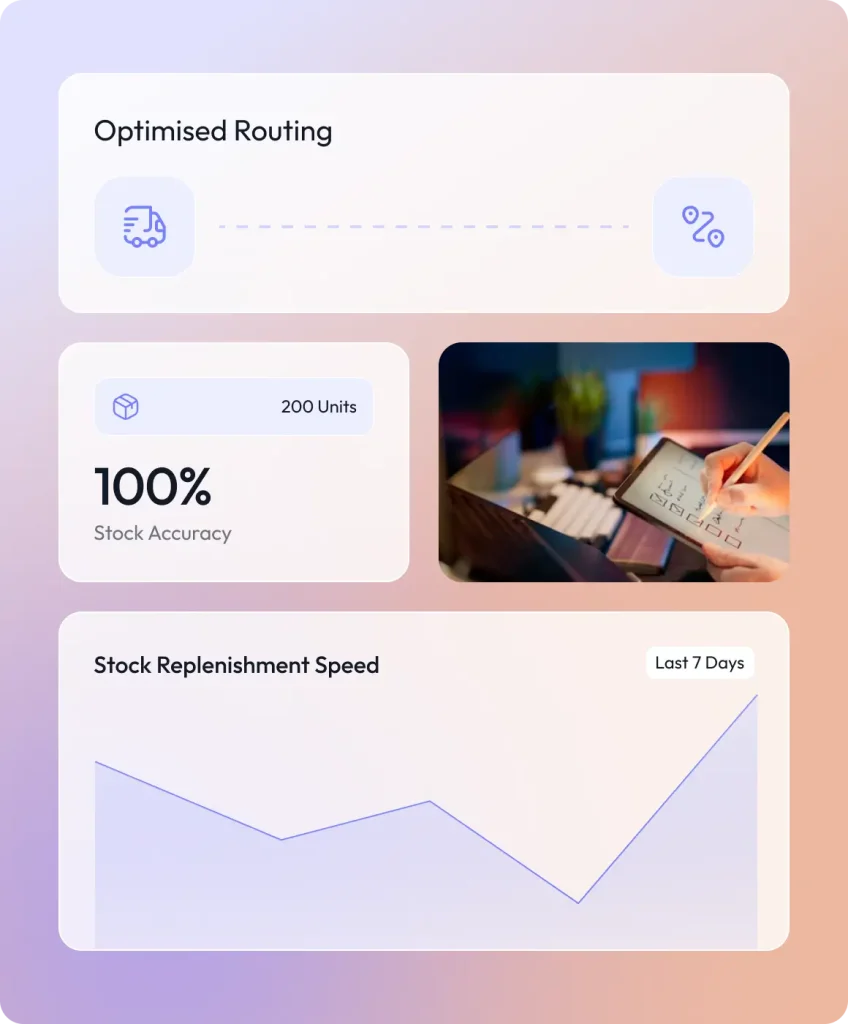

Results

Measurable impact from

inventory control

Real-time inventory visibility helps teams reduce shortages, cut excess stock, and keep technicians productive with the right parts available.

Control inventory in real time.

FAQ

Common questions about inventory visibility, replenishment, integrations, and scaling warehouse operations with Dobby.

Yes. Manage purchase orders, supplier catalogs, and receiving workflows to keep replenishment organized and traceable.

Yes. Monitor inventory per zone, including cold rooms or separate storage areas, with clear visibility across all locations.

Yes. Technicians can request parts directly from the mobile app to speed up replenishment and avoid delays.

Yes. Parts can be assigned to each job, helping you track usage, costs, and availability per service task.

Yes. Stock levels update in real time as parts are received, moved, or used in the field.