Cost per ticket is the clearest way to understand the true financial impact of every service visit in your coffee service business.

If you measure and track it accurately, you can reduce waste, improve efficiency, and protect margins. All without increasing the workload of your technicians or adding more headcount to your team.

In this blog, we’ll break down what cost per ticket means for coffee operators, what drives it up, and how platforms like Dobby help reduce it through connected data, smarter planning, and automation.

What is cost per ticket (and why it matters for service teams)

Cost per ticket is the average expense your company incurs to resolve a single customer support or service request.

It is calculated by dividing the total operating expenses of a service over a specific period by the number of tickets resolved during that same period. This metric helps companies evaluate the cost-efficiency of their support operations.

For coffee and vending operators, calculating cost per ticket involves considering every expenditure it takes to complete a service job and dividing it by the total tickets resolved.

Cost per Ticket = (Technician labor + travel + parts + admin time) / total tickets resolved.

Based on this formula, you can see how even an extra 15 minutes per call can significantly impact the cost per ticket of your company. For example, if your team handles 2,000 service calls monthly, an average of 15 extra minutes per job equals 500 wasted technician hours. That’s more than three full-time weeks of lost productivity.

That’s why it’s important to reduce this. But coffee operators think reducing per-ticket cost requires adding more technicians or increasing the workload of their existing team.

But that’s not the case. We’ll explore more about how you can reduce this, but first, let’s understand some of the cost drivers of coffee service tickets.

5 cost drivers behind every coffee service ticket

Here are some of the factors that increase the operating expenses of your business, which in turn increase the cost per ticket.

01

Technician inefficiency

02

Repeat visits

03

Admin overhead

04

Inventory mismanagement

05

Poor scheduling visibility

Technician inefficiency:

If your technicians are spending most of their time on the road due to poor route planning, your cost per ticket would automatically increase. Let’s say a technician in your team could complete 5 jobs a day, but because these jobs were located in different parts of the city, they could only manage 2. This reduced their efficiency with no fault of theirs.

Repeat visits:

Technicians in your coffee service team should be able to complete the jobs on the first visit. But if they have incomplete job data or any machine part missing, they’d have to revisit the job. This again increases your operational costs in terms of technicians' time, travel costs, and customer experience.

Admin overhead:

This is quite overlooked because most service managers assume manual reporting is part of their job. So they create routes, track and assign jobs, and manage inventory all through spreadsheets and manual systems, which increases admin overhead. That leaves little time to actually focus on how to grow your coffee service business.

Inventory mismanagement:

While there are multiple ways to manage inventory, like centralized or decentralized, it is only efficient if you oversee it correctly. When parts aren’t tracked properly, technicians spend hours sourcing what they need, or worse, they drive back to the warehouse mid-day. This disrupts schedules and inflates both travel and labor costs.

Poor scheduling visibility:

Your technicians should have even workloads and fewer idle hours if you want to reduce your cost per ticket. Yet, it is the most common cost driver for coffee operators. One technician is often overbooked and has to travel across the city, while another has 4 hours free on their workday. All because of poor field service route planning.

How to calculate your true cost per ticket (with example worksheet)

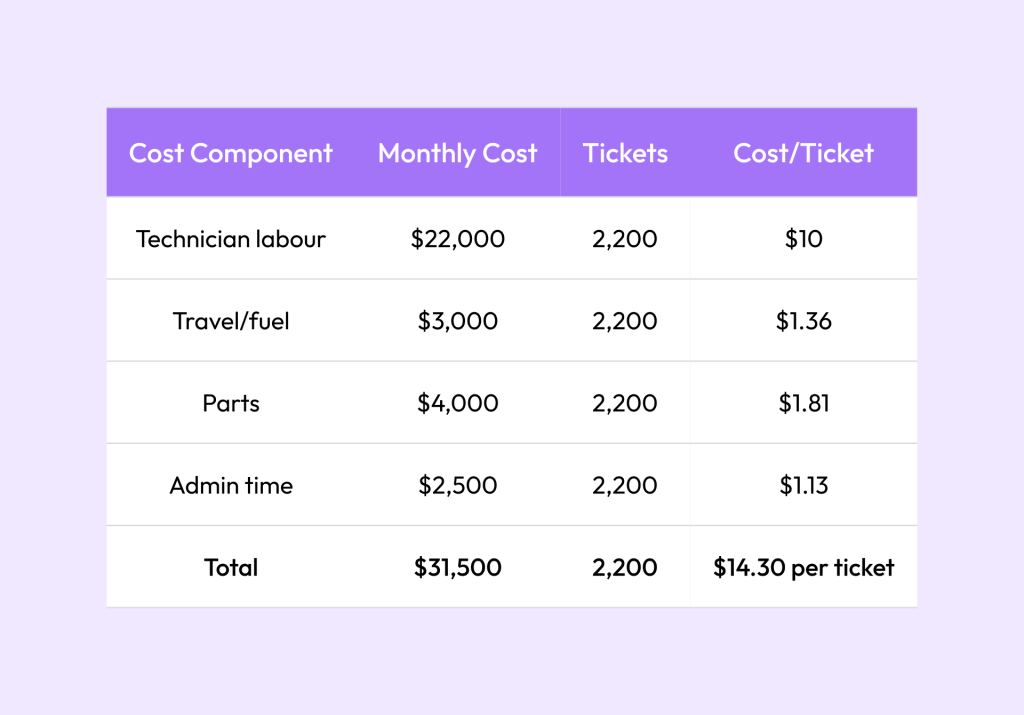

Consider this example to calculate the cost per ticket of your service business. For this, we’ve assumed that the monthly tickets are 2,200 while the cost components vary.

That means each service call costs roughly $14.30 to complete. But what happens if your monthly costs rise by just 5% while ticket volume stays the same? Even small percentage changes can have noticeable effects.

A modest 5% rise in costs increases the cost per ticket from $14.30 to $15.03, nearly a $0.73 jump per call. Across thousands of tickets per month, that’s a $1,575 difference!

Conversely, even a 5% reduction in these same costs, from $31,500 down to roughly $29,925, can reduce the cost per ticket to around $13.60, significantly boosting your profitability.

That’s why tracking and managing these costs proactively is so important. Here are a few ways to do that.

5 ways to reduce cost per ticket (without cutting corners)

Reducing cost per ticket at your business requires a holistic approach where you’re reducing the operational cost of multiple factors, like the ones we’ve listed above. You can either do all or figure out where most of your expenses are coming from and start from there.

01

Automate route planning

02

Give technicians full job context before arrival

03

Balance technicians workloads

04

Use predictive maintenance to stabilize workloads

05

Automate ticketing and reporting

1. Automate route planning

Automated route planning can reduce travel time and idle hours by assigning jobs based on technician location, skill, and availability. It also frees up the managers’ time to focus more on the business analysis part than on manual scheduling.

Operators using automated route planning often see up to an 11% increase in operational efficiency of their team.

Through Dobby, a CRM designed specifically for coffee operators, you can see these adjustments happen in real time. So when traffic or a cancellation changes the day, your schedule updates automatically.

Read our detailed guide on the hidden costs of manual route planning to know more.

2. Give technicians full job context before arrival

3. Balance technicians workloads

Unbalanced schedules cause stress and inefficiency. A few overworked technicians burn out, while others sit idle.

To balance workloads, you can start tracking utilization through a shared dashboard or a simple weekly review. But even that requires manual effort, planning, and doesn’t guarantee real-time assigning or redistribution of jobs.

With Dobby’s unified scheduling, service managers can see capacity in real time and redistribute jobs instantly, so every technician hour delivers value. It also helps with improving predictive maintenance. Let’s see how.

4. Use predictive maintenance to stabilize workloads

When service teams rely only on urgent repair calls, technicians and managers end up reacting to problems instead of planning their day. Predictive maintenance helps prevent that by using data about machine use and service history to schedule visits before machine downtime occurs.

For example, if a technician finishes a job early and updates it in real time through the Dobby app, managers can immediately see the available free time and assign a quick maintenance visit nearby.

This keeps workloads balanced, reduces idle time, and helps teams stay productive. All the while improving customer satisfaction.

To reduce your cost per ticket, the next thing to focus on is the ticketing and reporting process.

5. Automate ticketing and reporting

Administrative work often goes unnoticed. Service managers spend hours creating tickets, updating reports, or consolidating data. This work looks productive, but doesn’t add any profit to your company.

Automating these tasks can save service teams several hours per week and drastically improve reporting accuracy.

In Dobby, ticket creation, time tracking, and reporting are all automatic. Service data flows directly into dashboards and invoices, cutting repetitive work and freeing teams to focus on service quality.

The improvements we’ve suggested above work best when applied consistently. You can start by focusing on one area at a time. But with Dobby, you can easily improve each of these metrics together, without overwhelming your team. Read on to see how.

How Dobby helps reduce the cost per ticket for coffee operators

Dobby, the best CRM for coffee operators, gives coffee and vending service businesses full visibility into their cost per ticket. It connects every part of the operation, like technician schedules, travel data, inventory, and invoicing in one system.

Here’s how it works:

Connects technician, ticket, and parts data to show the real cost of every job.

Highlights inefficiencies like repeat visits or unbalanced routes before they impact margins.

Automates reporting so CFOs and service managers can see exactly where savings are coming from.

Companies using Dobby see up to 393% increase in their net profits. All because they get visibility into their costs, reduce their fuel spend, and achieve a higher technician utilization overall. By simplifying the operational backbone, Dobby helps teams spend less time managing and more time serving their customers.

See how Dobby helps coffee operators measure and reduce cost per ticket, without adding headcount. Get in touch!

Reduce cost per ticket of your coffee service team

The Dobby platform helps you reduce inefficiencies, deliver exceptional customer experiences, and drive profitability with the tools you need—all in one place.

Any Query? We Got You Covered!

FAQ’s

What is a good benchmark for cost per ticket in coffee service operations?

How can small coffee operators track cost per ticket without complex tools?

Why does technician utilization affect cost per ticket so much?

Technician time is your largest expense. If technicians spend too much time traveling or waiting for approvals, they will complete fewer jobs, raising the cost per ticket. Improving scheduling and data access directly lowers costs.

How often should service managers review cost per ticket data?

Can improving customer communication lower cost per ticket?

Yes. When customers share accurate issue details and updates are logged quickly, technicians can arrive fully prepared, reducing repeat visits and unnecessary travel, lowering cost per ticket, and improving satisfaction.