When your inventory is managed well, technicians arrive prepared, customers see reliable fixes, and financial performance stays strong. But when it slips, the problems show up fast as missed repairs, wasted travel, and higher costs.

Many businesses believe their inventory challenges stem from choosing the wrong management system. In reality, the real difference comes from the tools you rely on to manage stock. The right tools create visibility, streamline replenishment, and link inventory directly to service delivery. Without them, even the best strategy can fall short.

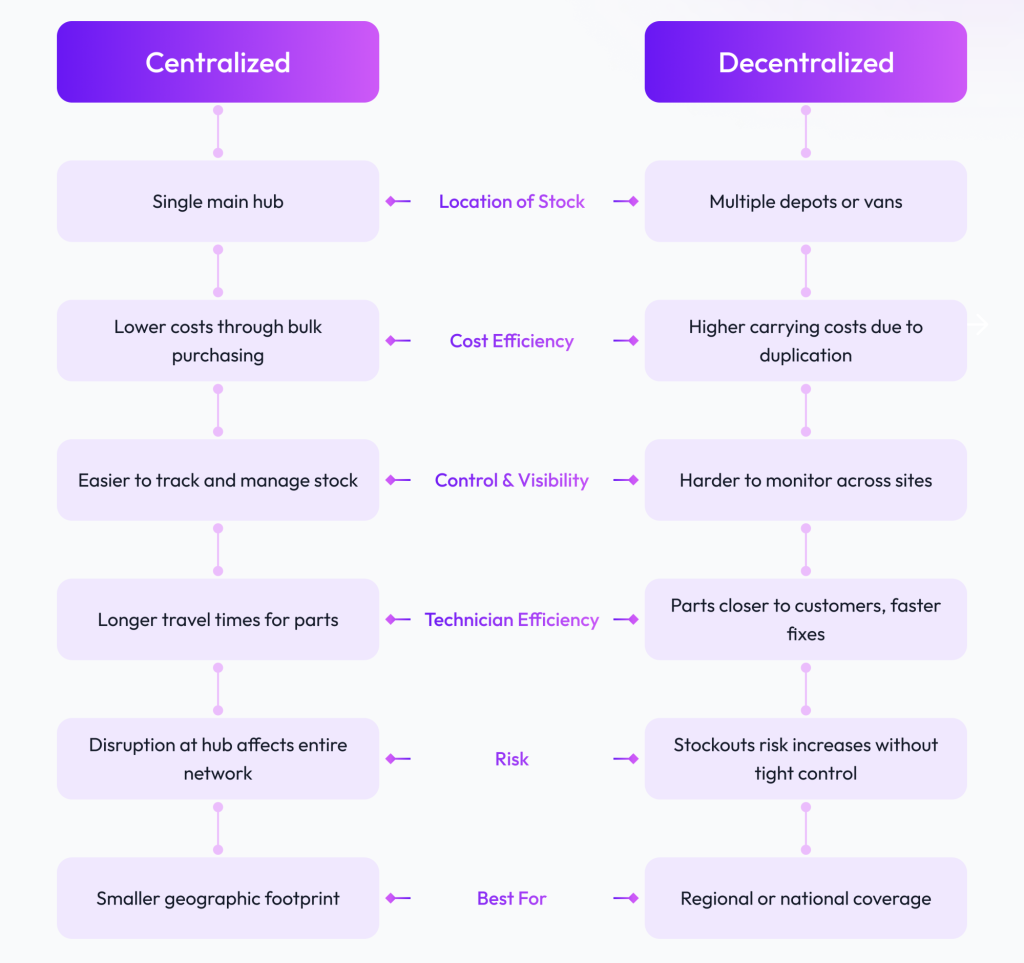

In this blog, we’ll look at centralized and decentralized inventory management, explore their advantages and challenges, and show why the outcome often depends less on the model itself and more on the tools that support it.

What is centralized inventory management?

Centralized inventory management is a strategy where all of a business’s inventory data, storage, and decision-making processes are controlled from a single, unified system or physical location. This helps provide a real-time, complete view of stock levels across all sales channels, warehouses, and distribution centers.

For many operators, this model feels clean and easy to control. It keeps purchasing simple, reduces duplication, and allows for stronger oversight.

Benefits of centralized inventory management include:

Cost savings due to bulk purchasing.

Easy maintenance of accurate stock records.

Low overhead because of fewer locations to manage.

But a centralized inventory management system also has some drawbacks:

Technicians may spend more time traveling to pick up parts.

Service delays increase if replenishment takes too long.

A single disruption at the hub can slow down the entire network.

Centralization works best when your footprint is limited to a smaller geography or when you can afford longer lead times between stock and site. But for operators covering multiple regions, these bottlenecks can add up fast.

Now let’s take a look at what decentralized inventory management means.

What is decentralized inventory management?

Decentralized inventory management is a strategy where a business stores its products in multiple, geographically spread-out warehouses or locations instead of a single central facility. This can be multiple depots, regional warehouses, or even directly into technicians’ vans.

This approach is all about positioning parts closer to the point of use. Here are some other benefits decentralized inventory offers for businesses:

Parts are closer to the customer, enabling faster fixes.

Reduced technician downtime and fewer wasted trips.

Higher customer satisfaction with quicker service.

But you should also consider some of its drawbacks before deciding which model works best. Decentralized inventory leads to:

Higher carrying costs from duplicated stock across locations.

Increased difficulty maintaining visibility and control.

Risk of stockouts if replenishment isn’t tightly managed.

Decentralization can be highly effective for regional or national operators, but without the right systems in place, it can just as easily lead to inefficiency and waste.

Top 3 questions to ask when choosing the right approach

Before committing to centralized or decentralized strategies, service leaders should step back and ask three key questions:

Question 1: What does your service footprint look like?

If your coverage is highly localized, centralization may keep costs low, help with field service optimization and simplify stock control. Local depots or van stocking may not be necessary if most customers are within a short drive of your hub.

However, if you operate across multiple regions or nationally, decentralization (or a hybrid model) often works better. In these cases, regional depots or stocking vans can directly reduce technician travel, help with real-time inventory tracking, improve first-time fix rates, and keep response times in line with customer expectations.

Question 2: How large is your team, and what level of stock access do they need?

A small team with limited vans can work effectively from a single hub, since parts and consumables can be managed centrally without creating major delays. This setup keeps costs predictable and stock control simple.

But if you have a larger field force, you require more flexible access points to avoid bottlenecks. For these teams, strategically placing inventory in regional depots or stocking vans directly can ensure that technicians spend more time fixing machines and less time traveling. This also helps service managers maintain SLA commitments across a broader footprint.

Question 3: What SLA commitments and growth goals are you trying to meet?

Think about how your service commitments and long-term growth targets align with your inventory strategy.

Are you expanding into new regions and need to ensure parts availability everywhere? Or are you focused on building a leaner operation while keeping customer satisfaction high? The balance between service speed, cost efficiency, and scalability should guide which model fits best.

But here is where this debate between centralized vs. decentralized inventory management can come to an end. You don’t need to choose one of these models. If you want to get the benefits of both, choose a hybrid model.

A hybrid model allows operators to centralize certain slow-moving or high-cost items while decentralizing fast-moving consumables or critical spare parts. This balance helps keep costs predictable while ensuring technicians always have access to the essentials they need in the field.

If you choose a hybrid model, does that mean you have to maintain your inventory across multiple tools and manage different CRMs to get visibility into your stock?

Not really, because that’s where Dobby helps.

How Dobby helps operators manage both models

For most businesses, the choice between choosing a centralized, decentralized or a combination of two comes down to visibility and control. They believe one model would offer better visibility over another, and that becomes a deciding factor.

In practice, both models have blind spots. Central hubs can feel easier to oversee, but make it harder to understand what is happening in the field. Decentralized stock gives speed but makes it more difficult to maintain an accurate picture of costs and usage across the network.

This is where Dobby makes the difference. With Dobby’s warehouse management system, you don’t have to choose between efficiency and flexibility or sacrifice visibility for speed.

We offer:

Real-time inventory tracking across warehouses and technician vehicles, so managers always know what’s available, what’s needed, and where to find it.

Help eliminate stockouts and overstocking with automated reorder levels that keep inventory at the right balance.

ERP-integrated management for real-time updates and accurate forecasting, reducing manual work and improving data accuracy.

Optimize technician vehicle stock by tracking and managing van inventory, equipping technicians with the right parts to improve first-time fix rates.

Simplify multi-location warehousing by managing and synchronizing stock across depots and regions, making it easier to scale operations without adding unnecessary complexity.

Want to reduce vending machine downtime and keep every machine working?

Explore more insights and guides from our experts

1. Choosing field service management software for your coffee service business? Ask these 5 questions first

2. How vending machine management software fixes your data chaos

3. The 5 hidden costs of manual route planning for coffee & vending technician

4. Digitisation made simple: A practical guide for coffee service operators [2025]

5. How to grow your coffee service business? 4 steps you can take today